Background:

A local home heating manufacturer wanted to update one of its wall mounted gas panel heaters.

From a manufacturing standpoint, a number of issues were important when considering a new design including low tooling costs and working within factory capabilities.

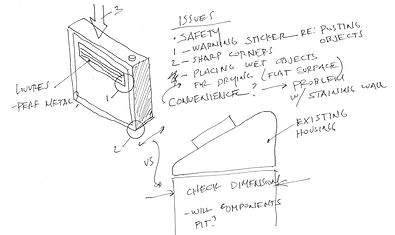

From a user standpoint, interviews with sales staff at a number of outlets revealed product issues including safety, convenience and appearance.

Problems and opportunities:

1. A warning label was being used as a deterrent to stop children placing objects through the heating vents.

2. The current manufacturing technique resulted in sharp corners which were potentially dangerous- especially for young children.

3. The wide, flat top of the product invited placement of wet objects for drying, which would sometimes result in staining of the wall behind.

4. The overall appearance of the product was dated and not consistent with other products in the range.

5. Existing components from other products in the range had the potential to be used in the new product update.

Key question:

How can existing components be reconfigured to create a safer, more user-friendly, visually appealing product?

Final proposal included:

1. Mesh screen behind vents to prevent objects from being placed inside the heater.

2. Use of existing rounded, angled top housing from another product- reducing the need for new tooling.

3. Rounded corners which conform to the shape of the top housing- making the product more user friendly and visually appealing.

4. Angled top which prevents objects being placed on top for drying purposes- minimising stain potential.

Wall mounted heater

new heater design

early production drawing

early project notes